Applications

Nano silica concentrates

Ready for future requirements? Our nanoparticles can make a small but subtle difference in your reactive resin system.

Evonik’s wide range of specialty chemicals enable our customers to make products that improve our everyday lives and create solutions for a better future. Our products may often only make a small and subtle difference, but always an important difference, and of course, this applies in the truest sense of the word with our nano silica concentrate technology.

While many nanotechnologies tend to be produced on a limited laboratory scale, our unique manufacturing process enables nano silica concentrates to be produced on an industrial scale. We offer our SiO2 concentrates in a wide variety of carrier systems on a ton scale, thus enabling the economical use of high-quality nano silica solutions in everyday products.

Let's get back to the small but subtle difference. With the help of nano silica particles, the properties and capabilities of a wide variety of materials can be significantly expanded and improved.

With our special matrix exchange process, we can introduce nanoparticles into different carrier substances such as epoxy, acrylic resins and several solvents achieving different particle sizes in the range of 20-80 nm, and filling levels of up to 50% nanoparticles. Of course, consistent and reproducible product quality is also vital.

The images above illustrate the dispersion and distribution quality of our nanoparticles at different levels of filling. The maximum loading level of our nanoparticles is defined by the viscosity of the final concentrates.

Under these well-known brand names Evonik has been offering its nano silica technology for many years:

- NANOPOX® (nanoparticles in epoxy resins)

- NANOCRYL® (nanoparticles in acrylic resins)

- NANOPOL® (nanoparticles in organic solvents)

Working in close cooperation with our customers, our experienced, technical team develops solutions for a wide range of applications, including:

- Structural adhesives

- Composites

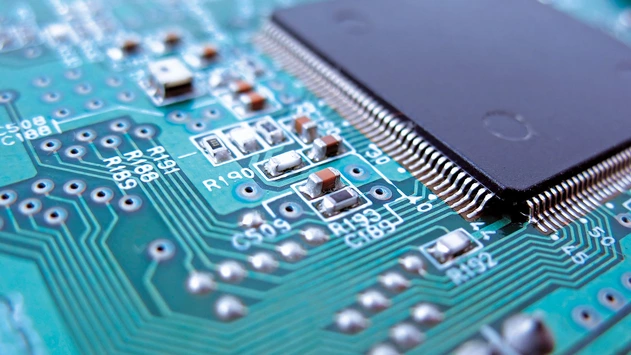

- Electronics

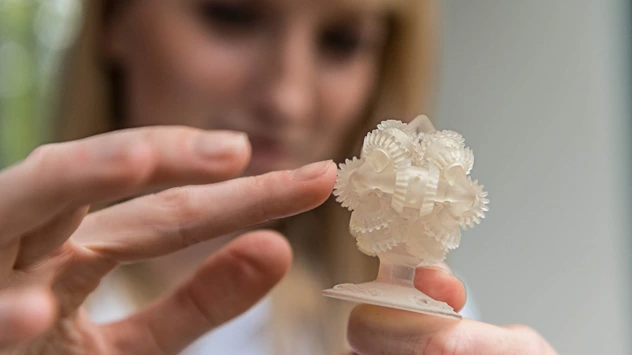

- Medical

- 3D printing

These applications benefit from the special capabilities of the SiO2 particles in a variety of ways, and the resulting nano silica composite materials can improve or change properties like:

- Improved mechanical properties

- Higher thermal conductivity and less sedimentation

- Transparent, filled formulations

- Improved permeability resistance

- Reduced shrinkage properties and coefficient of thermal expansion

- Improved toughening and fatigue performance

OUR TECHNICAL SERVICE CAPABILITIES FOR NANO SILICA CONCENTRATE CUSTOMERS

- Technical support and ongoing guidance

- Versatile testing equipment to test products in accordance to established technical standards

- From the development of customized formulations to individual product development for selected applications.

- Our mission is to deliver excellent service and create long-term value for our partners by turning our in-depth process knowledge and physicochemical expertise into high performance products and sustainable solutions.