Applications

Linerless Labels

No Liner – no waste. Linerless labels with Evonik’s TEGO® RC Silicones.

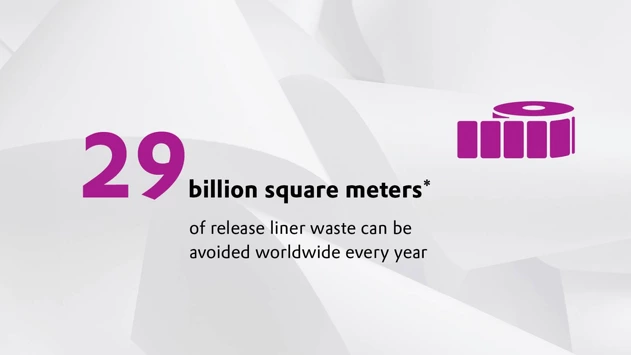

Labels play an important role in today’s e-commerce driven economy and the approximate 26 billion m2annual global production of pressure sensitive labels is expected to grow by more than 4% a year. One approach to reduce waste and costs are to make the backing paper thinner, reusing and recycling the release liner only applies for a minor portion. However, these cannot be the only answers to meeting today’s sustainability requirements for preserving natural resources, improving energy efficiency and reducing waste. The far more sustainable solution is linerless technology, which doesn’t require any backing carrier at all.

The very robust free radical curing mechanism of our TEGO® RC Silicones are the key for linerless label applications on a wide variety of paper and filmic surfaces. Curing at room temperature allows easy coating of thermal sensitive materials like thermal papers. Since the silicone curing is completed in fractions of a second, adhesive can be applied inline directly on one coating line. TEGO® RC's advanced curing technology allows paper and filmic labels to be siliconized on top of the print, with no interference with the substrate, dye and printing. The reverse side of the label is coated with adhesive and the label is rolled up without a liner, just like a tape.

Benefits of TEGO® RC Silicones for linerless label applications

- Enables flexible and customizable label lengths

- Surface protection against water, oil and scratches

- Reduction of logistics footprint (storage, transport etc.)

- Extended reel duration; 50% more labels on reels

- Less downtime in label dispensing

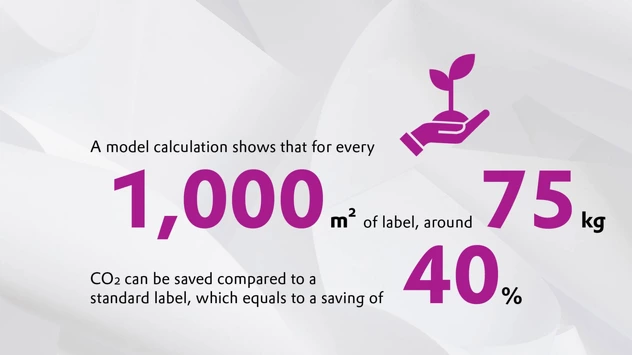

- Saves up to 40 % materials – improved waste management

- Better Co2 footprint

Linerless label applications improved using TEGO® RC Silicones

Linerless labels are already being used effectively in numerous applications, from health and beauty, food and beverage to postal and logistics. Linerless labels are especially suitable for thermal labels required to provide variable print information. Likewise, prime labels can also be produced and wrap around labels are rapidly growing in food packaging. Today there are several performance and ecological benefits behind why more industries are increasingly interested in using linerless labels, and the label industry is ready for the next step – getting rid of the release liner!

Variable information print (VIP) thermal labels represent a major part of the pressure sensitive label market. Key applications in grocery weighing scales, fast food point of sale solutions, business form applications, warehousing, and transportation are all being driven by increasing online sales.

Standard VIP thermal labels can be easily adapted to liner free labels and explains why today many thermal labels are already linerless. Our UV curable TEGO® RC Silicones work well without activating the heat sensitive dye of the thermal paper. The release coating is applied on top of the thermal sensitive face stock and cured by UV radiation adhering in a fraction of a second. The adhesive is then coated on the backside when the label is wound on itself like a tape and the thermal printing of the image appears underneath the translucent silicone coating.

Evonik’s TEGO® RC solutions are specifically designed for thermal linerless label applications and these release coatings can be applied for manual and auto applied labels. Contamination of the electronic printing head and label cutting tools is reduced to allow high production efficiency, long printing cycles at very high quality.

Benefits of TEGO® RC Silicones for thermal labels

- Flexible label lengths

- High tact rates

- Premium surface look and feel

- Improved surface protection against scratch, water, oil, and abrasion

- High accurate scan read rates

Today, linerless technology and applicator systems are available for both primary and secondary product decoration labels. Linerless technology offers multiple opportunities for decorative labels for packaging containers and consumer products.

In standard prime labels the release liner plays an important role in the production for both hand-applied and automatically dispensed labels, i.e., for die cutting or during the dispensing. In the production of prime linerless labels a process liner is laminated to allow for die cutting and the removal of the matrix. After dispensing the labels with a standard label dispenser, the process liner is rewound and can be reused multiple times before being recycled. Separation of single labels can also be achieved through a laser perforation step.

In addition to no liner, no matrix, lower thickness and reels that can hold many more labels, there are also several other benefits of choosing linerless labels, these include less raw materials, improved logistics and storage, and lower CO2 .

Benefits of TEGO® RC Silicones for prime labels

- Applicable for, but not restricted to rectangular shaped labels

- For decorative and informational printing

- Labels can be separated by cutting tool or via perforation

- Die cutting and dispensing through reusable process liner

- For microperforated labels no process liner for dispensing is needed

- Full in-line label finishing

- Laser printing of variable information prior to dispensing possible

Sleeve labels are a subgroup of prime labels. One major application of prime labels is so called wrap around labels printed on carton board paper, standard paper grades or filmic substrates, which can all be printed rectangular to the roll direction. These linerless labels are pre-printed (one and two side print labels are possible) and often coated with a pattern/stripe coating of silicone and adhesive. This application is ideal for packaging of fresh food (e.g., poultry, meat, fish, desserts).

Today innovative solutions are enabling linerless labels to take over additional functions such as becoming the lid of a fruit box. In-line variable data can be added with laser print during the dispensing process on the container, and these innovative solutions on the material and equipment help to broaden the opportunities for linerless labels.

Benefits of TEGO® RC Silicones for wrap / sleeve labels

- Printed paper or film for the label face

- For decorative and informational printing

- Pattern coating of the silicone and adhesive is possible

- Produced as a linerless roll label

- Label is cut on a special dispensing tool

- Variable information printing prior to dispensing possible

- Different label formats (top, one/ two sided/C-wraps) are possible

Sustainable smart solutions

Linerless labels have significant sustainability benefits saving up to 40% of materials and reducing CO2 emissions compared to conventional self-adhesive labels - where the liner accounts for up to 40% of the weight and is the major driver of the overall cost of materials. After the labelling process, the liner just becomes very expensive waste.

In the EU alone, around 400,000 tons of paper is disposed of every year, worldwide the figure is around 1.2 million tons. Although in the EU about 35% of the total waste of release liner material is fed back into recycling processes, a large part of the high-quality and costly cellulose paper still ends up in landfills or incineration, further adding to the waste problem.

Linerless solutions offer an overarching sustainability benefit that the whole value chain can take advantage of. The converter as well as the user generate no release liner waste that they need to take care of in terms of collecting and disposing, and sometimes even paying fees. A model calculation shows that for every 1,000 m2 of label, around 75 kg of CO2 can be saved compared to a standard label, equating to a saving of around 40%.

Increasing public discussions about environmental protection is changing consumer behavior to be more ecological, and manufacturers are adapting too, and the search for environmentally friendly packaging solutions is increasing. The relevance of this solution will grow in times when e-commerce reaches new records and all-time highs year-on-year.

|

Sustainable, flexible, reliable and cost-effective labelling – with our TEGO® RC silicones coatings to deliver the right ecological and economic balance. |

Our global RC Silicone team can support you with

- Training and assistance in application & processing of our TEGO® RC Silicones coating

- Technical service during start-up phase and on-going production support

- Utilize our wide network of contacts to equipment and machine suppliers

- Innovative developments for future challenges

- Long-term relationships based on trust